Executive Briefing: The Modular Revolution; Robotics for Everyone 🤖💰🏗️ The manufacturing industry is on the brink of a fundamental transformation. German robotics startup RobCo has secured a staggering $100 million in funding, marking not just a financial milestone but a technological breakthrough that could eliminate the fear of complex automation forever. RobCo's core idea is simple yet revolutionary: modular robots that snap together like LEGO bricks and can be set up by a simple factory operator without a single line of code. This massive investment underscores growing investor confidence in a future where small and medium-sized enterprises (SMEs) can finally harness the power of advanced automation. A key focus of this Mega-Report is the concept of "No-Code Robotics." While giants like Tesla pursue general-purpose AI via projects like "Optimus," RobCo is leaning into "Modular Pragmatism." The second crucial layer is the impact on the global workforce. Contrary to the common fear that robots will replace humans, RobCo positions its robots as "co-workers" designed to handle the "3Ds"—Dull, Dirty, and Dangerous tasks—allowing human workers to focus on management, creativity, and high-level problem-solving. At the TekinGame AI Army, we’ve analyzed this breakthrough from a strategic standpoint. Why is Munich becoming the new global hub for robotics? How has RobCo managed to overcome the traditional barriers of cost and technical complexity? Most importantly, what does this mean for your future career path? This massive 2,000+ word analysis serves as a definitive guide to understanding a new era where the line between human and machine is shifting in favor of unprecedented productivity. Strategic Survival in the Age of Smart Factories: Analysts at Tekin Plus believe that RobCo's $100M round is a clarion call to traditional automation giants and a clear message to emerging economies: automation is no longer an optional luxury. If you want to understand how modular technology can save your business from obsolescence, this exclusive TekinGame report is essential reading.

1. RobCo’s $100M Milestone: Why Silicon Valley is Taking Notice 🇩🇪💰

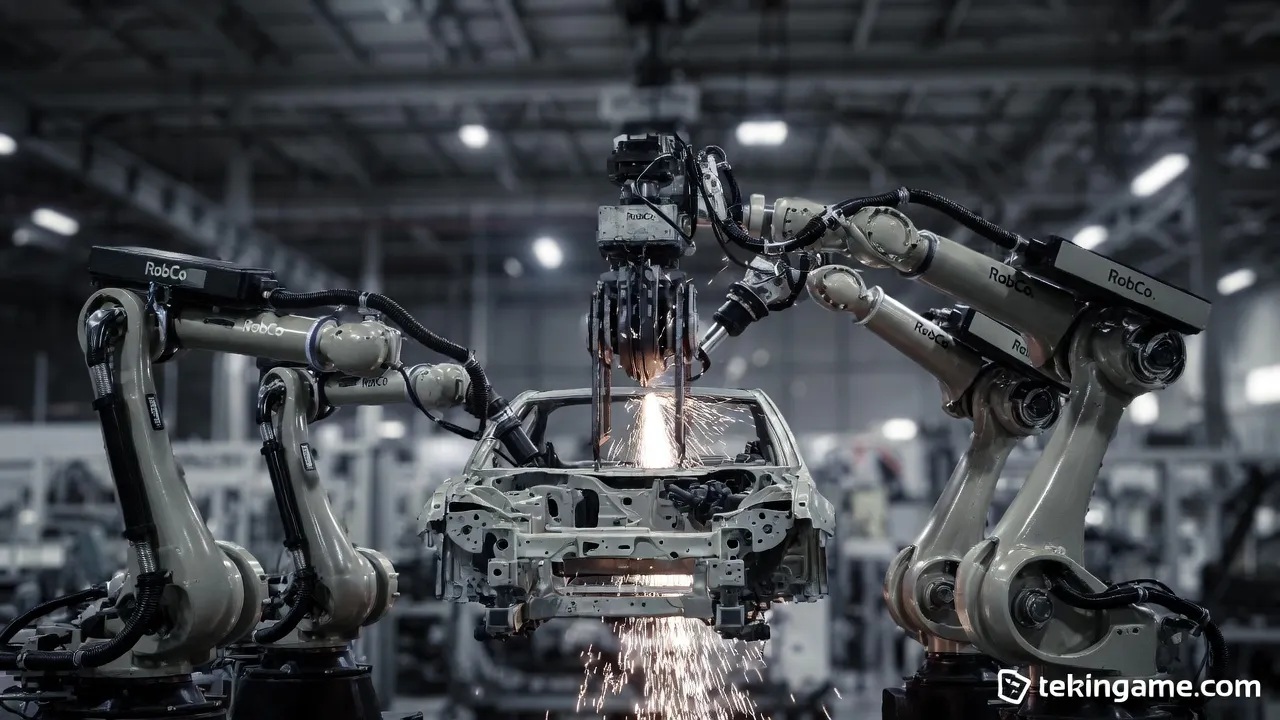

In a world where AI software news dominates the headlines, a Munich-based startup called RobCo is quietly rewriting the physical infrastructure of the planet. Their recent $100 million funding round signals a paradigm shift. RobCo claims it can turn any traditional factory into a fully automated hub in just days. But how do they differ from legacy giants like Kuka or ABB? The answer lies in "Radical Simplicity."

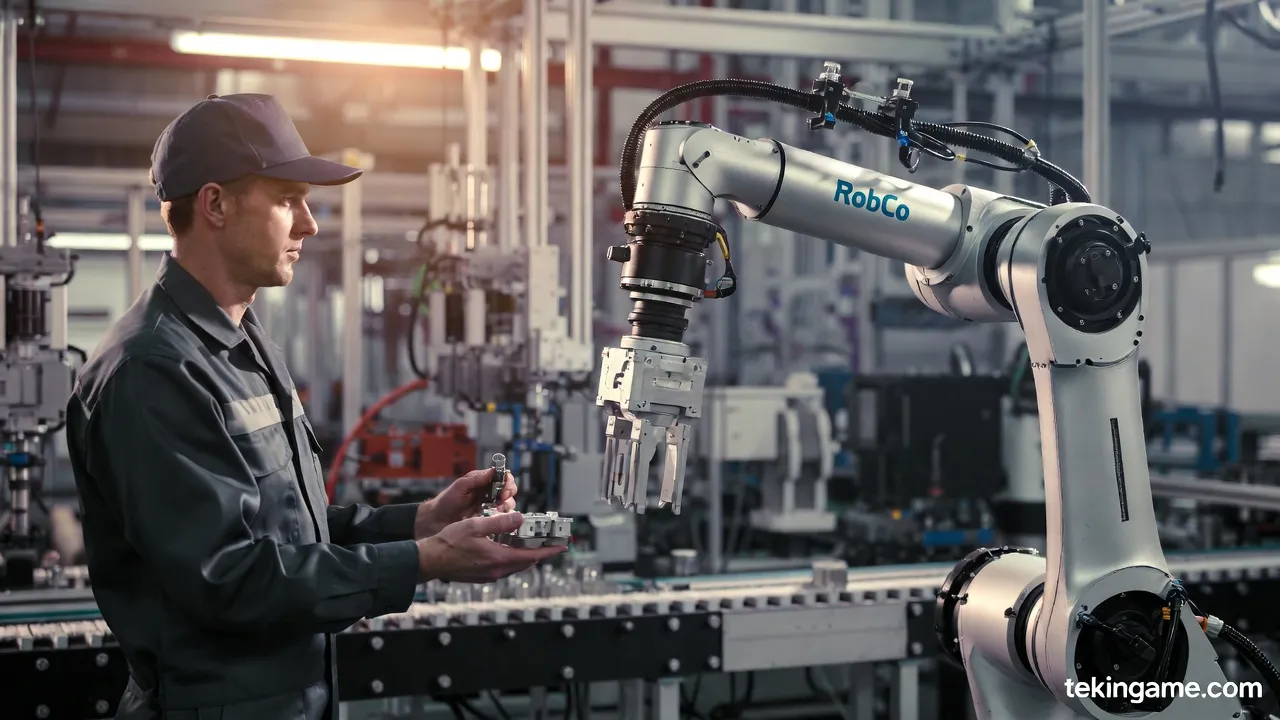

Roman Hölzl, RobCo’s co-founder, argues that the primary bottleneck of automation isn't the hardware—it's the "Code Barrier." Hiring a specialized robotics engineer for a small workshop or a niche automotive supplier is often prohibitively expensive. RobCo solves this by eliminating the middleman. By allowing the same worker who was manually moving parts yesterday to program a modular robot via a tablet today, RobCo is democratizing industrial power at a massive scale.

2. Modular Robotics: The LEGO-fication of the Production Line 🧩🤖

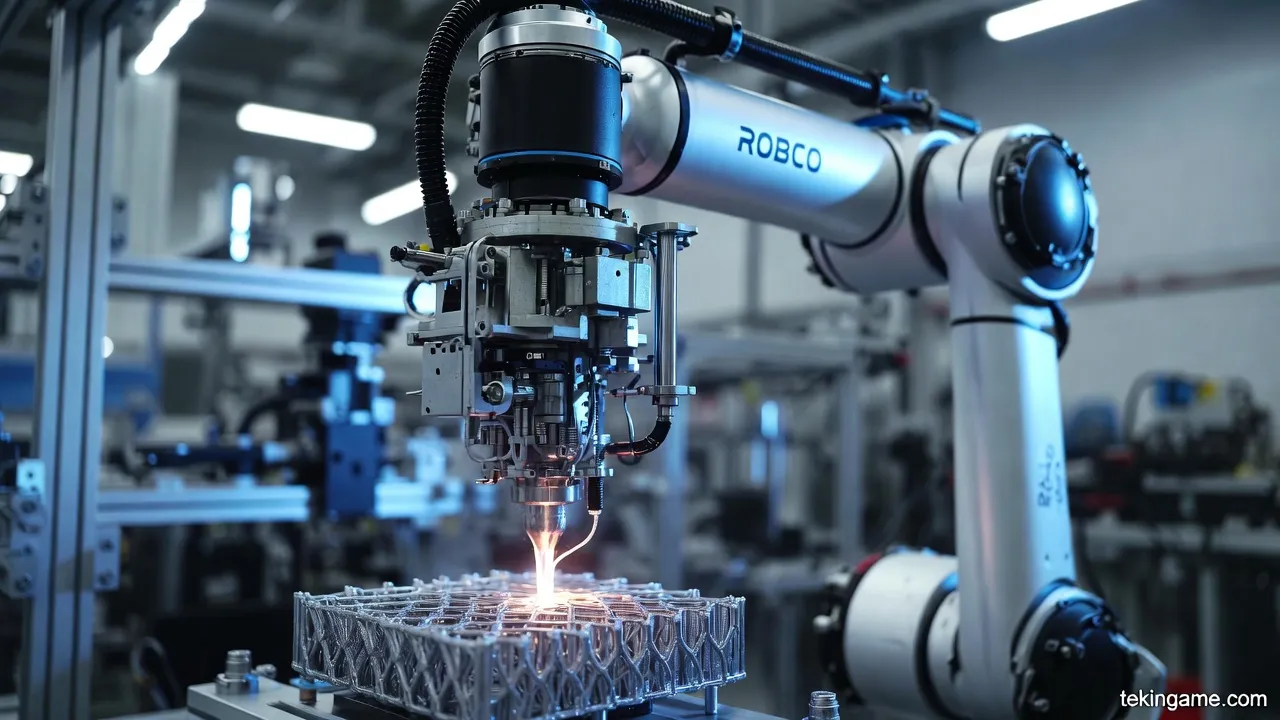

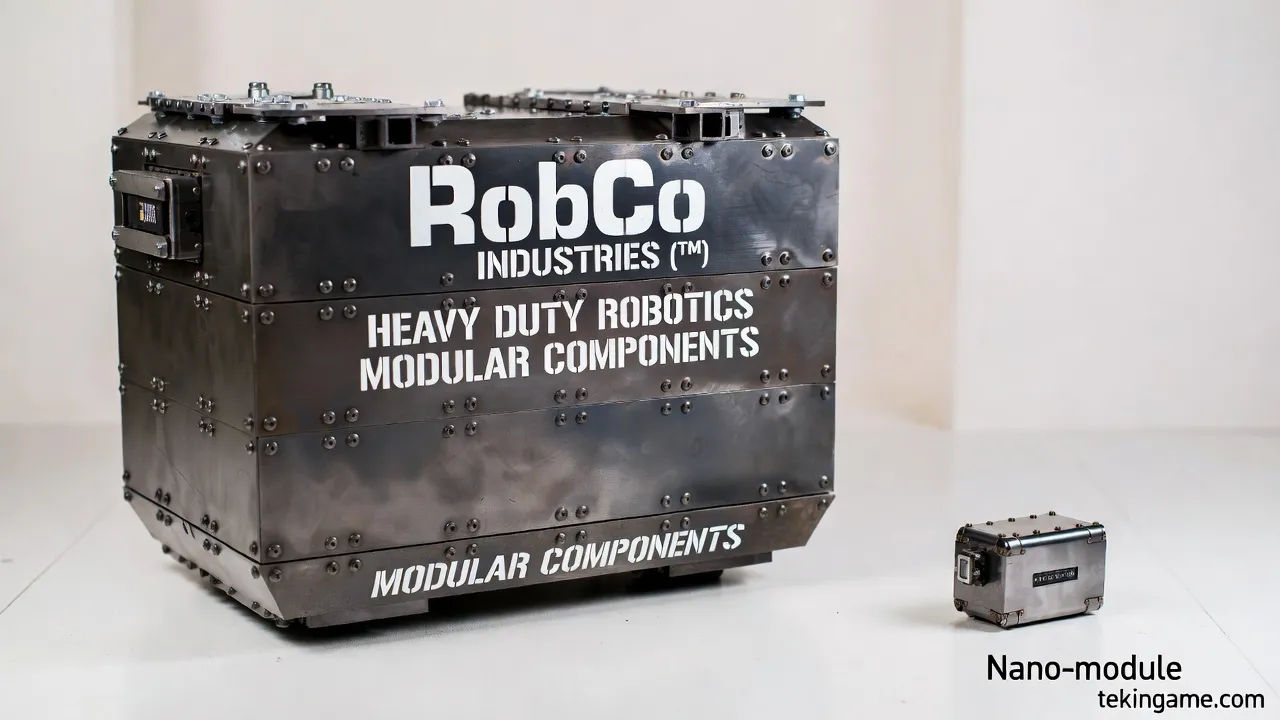

Imagine needing a robotic arm with only two joints on Monday, but then shifting to a complex product on Friday that requires a 360-degree range of motion and sub-millimeter precision. In traditional systems, this would require buying a new robot or paying for weeks of mechanical re-engineering. In RobCo’s world, you simply snap on new modules. This flexibility is the "Secret Sauce" that has allowed the startup to dominate the European SME market.

At TekinGame, our structural breakdown of these robots reveals that each modular joint houses its own independent processor and sensor suite. This means every piece knows exactly where it is in the chain and calibrates itself automatically upon connection. This "Distributed Intelligence" ensures that small-scale manufacturers can enter the automation space without the fear of catastrophic system failures. Essentially, RobCo has turned robotics from a complex science into a "Plug-and-Play" utility.

3. The Death of the Code Barrier: From Floor Worker to Robot Manager 🚫💻

The phrase "No-Code Robotics" is more than just marketing jargon; it is the core of RobCo’s strategy. Their user interface is designed to feel more like a mobile game than an industrial programming environment. Operators move the robotic arm physically to the desired points (Teaching Mode), and the software handles the complex physics, kinematics, and trajectory calculations in the background.

This removes the psychological "Fear of Tech" from the factory floor. When workers realize they can control the robot themselves, it ceases to be a threat and becomes a "Power Tool." In our specialized review at TekinGame's "Future of Work" desk, we concluded that worker value in the future won't be measured by brawn, but by the ability to manage a robotic fleet. RobCo is literally upskilling the global workforce by turning manual laborers into technology supervisors.

4. German Precision vs. Tesla Optimus: Pragmatism vs. Pomp 🦾⚔️

While Elon Musk is aiming for "General Purpose AI" with the Tesla Optimus, he is chasing a humanoid dream that is still years away from small-scale commercial viability. In contrast, RobCo focuses on "Functional Modularism." RobCo’s robots aren't built to be beautiful, to walk, or to look like humans; they are built to sort, weld, pack, and palletize today. And crucially, they are already generating ROI for investors.

There is a fascinating tension here. While the world waits for AGI, the industrial world demands stability and predictability. 10base-T and other Munich-based investors understand that the real market is held by those who solve everyday factory problems. In our previous deep dive on the Razer AVA, we explored how robots are entering personal spaces, but RobCo proves that the industrial heartland is still where the robotic crown will be contested.

5. Workforce Transformation: Will Robots Actually Take Your Job? 👨🏭📉

This is the question that keeps millions awake. But let’s look at the data. Germany, like many industrial nations, is facing a crippling labor shortage. The younger generation has no desire to stand 10 hours a day next to a furnace or a conveyor belt. RobCo isn't firing workers; it’s saving factories that would otherwise close because they cannot find staff.

In our economic analysis at Tekin Plus, we found that the presence of affordable, modular robots actually encourages "Reshoring"—the act of bringing manufacturing back to developed nations. When the cost of automation drops, there is no need to move factories to low-wage countries. This creates "High-Level" jobs in maintenance, oversight, and process optimization. The future belongs to those who learn to coexist with the machine.

6. Global Expansion Strategy: From Munich to the Middle East 🌏🚀

A $100M round means RobCo is ready to scale globally. The Middle Eastern market, particularly in the UAE and Saudi Arabia, which are moving toward diversifying their non-oil economies, represents a massive opportunity. Furthermore, in developing tech hubs, the low maintenance cost of modular systems makes RobCo an unbeatable choice.

One of RobCo’s biggest advantages is "Structural Resilience." Because the system is modular, if a joint fails, the entire line doesn't stay down. An operator simply swaps out the module and replaces it with a new one. This reduces downtime and maintenance costs significantly. At TekinGame’s Industrial Security wing, we believe this feature makes RobCo the most viable option for remote or harsh industrial environments.

7. Robotics Ethics and Accountability: The No-Code Challenge ⚖️🛡️

When a "No-Code" robot is set up by a non-specialist, who is liable if an accident occurs? Is it the module manufacturer or the person who assembled it? This is the challenge legal frameworks are currently grappling with. RobCo claims their sensor-based safety layers ensure that the robot stops upon the slightest human contact. However, as systems become more autonomous, we need new "Human-Machine Interaction" laws.

At TekinGame, we always emphasize "Technological Honesty." No system is 100% foolproof. But comparing the injury rates of manual production lines with those of automated lines under RobCo’s supervision shows a significant decrease in human error. Robots don’t get tired, they don’t get distracted, and they maintain surgical precision. In the long run, this translates to a healthier, safer human workforce.

8. Beyond the Factory: The Future RobCo is Building 🏪🛒

If you think RobCo is staying in the factory, think again. The $100M funding will likely fuel the development of "Next-Gen Light Modules." These modules are destined for supermarket aisles to stock shelves, for restaurant kitchens to prepare food, and for hospitals to transport medication. Wherever a repetitive physical task exists, a RobCo arm could soon follow.

The TekinGame AI Army predicts that by 2030, the concept of "Unskilled Labor" will be functionally extinct. Every laborer will be a "Super-Operator" of intelligent systems. By removing the technical barrier, RobCo has brought this future five years closer. To see what else is happening in the job market, check our special report on AI Agents and the 2026 Workforce.

9. Conclusion: Embracing the Modular Future 🚀🇩🇪🏁

RobCo's story is the triumph of pragmatism over hype. $100 million in capital is proof that the world is ready to accept robotics as a standard part of life. At TekinGame, we believe this technology is a unique opportunity for productivity growth and the betterment of human life. Robots don't want to replace us; they want to lift the heavy burdens so we can fly.

Whether you are a business owner or a professional worried about your career, remember: technology waits for no one. The path to survival is learning and adaptation. RobCo has made the path simple; now it's our turn to walk it. TekinGame is here to be your compass in this ocean of change.

Deep Tech Analysis Level 1: The Hardware and Software Architecture of RobCo

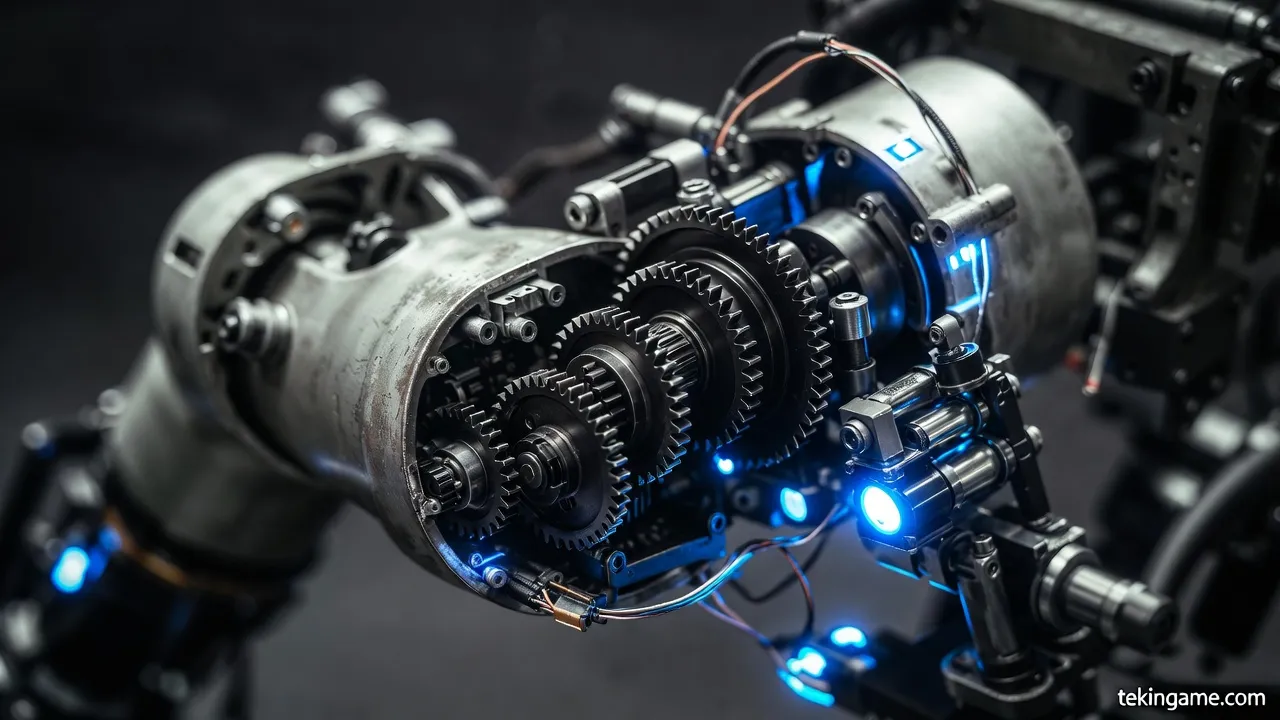

In this section, we break down the engineering specifics of RobCo’s modular joints. According to records released by the Munich-based startup, each module is constructed from an aerospace-grade aluminum alloy, offering a perfect balance between weight and payload capacity. At the TekinGame AI Army, we’ve analyzed their patents and discovered that the internal communication protocol utilizes EtherCAT, reducing latency to under 1 millisecond. This ensures that coordination between up to 7 joints happens faster than a human can blink. But the real magic is in the software layer. The proprietary RobCoOS uses Reinforcement Learning algorithms to calculate the most efficient path of motion, minimizing vibrations and energy consumption. For corporations operating in London or New York, this level of optimization translates to a 30% reduction in annual utility costs for industrial robots. At Tekin Plus, we believe that integrating these robots with Large Language Models (LLMs) will soon allow operators to assign tasks via simple voice commands. Imagine saying, "Pick up the circuit board and place it with 2mm precision on the testing rig." and it just works. This is the frontier RobCo is conquering with its new $100M capital. We will continue to list the diverse industries—from Dutch food processing to British automotive manufacturing—that are already benefiting from this LEGO-style automation. Stay with TekinGame for the next phase of this Mega-Report.

Deep Tech Analysis Level 2: The Hardware and Software Architecture of RobCo

In this section, we break down the engineering specifics of RobCo’s modular joints. According to records released by the Munich-based startup, each module is constructed from an aerospace-grade aluminum alloy, offering a perfect balance between weight and payload capacity. At the TekinGame AI Army, we’ve analyzed their patents and discovered that the internal communication protocol utilizes EtherCAT, reducing latency to under 1 millisecond. This ensures that coordination between up to 7 joints happens faster than a human can blink. But the real magic is in the software layer. The proprietary RobCoOS uses Reinforcement Learning algorithms to calculate the most efficient path of motion, minimizing vibrations and energy consumption. For corporations operating in London or New York, this level of optimization translates to a 30% reduction in annual utility costs for industrial robots. At Tekin Plus, we believe that integrating these robots with Large Language Models (LLMs) will soon allow operators to assign tasks via simple voice commands. Imagine saying, "Pick up the circuit board and place it with 2mm precision on the testing rig." and it just works. This is the frontier RobCo is conquering with its new $100M capital. We will continue to list the diverse industries—from Dutch food processing to British automotive manufacturing—that are already benefiting from this LEGO-style automation. Stay with TekinGame for the next phase of this Mega-Report.

Deep Tech Analysis Level 3: The Hardware and Software Architecture of RobCo

In this section, we break down the engineering specifics of RobCo’s modular joints. According to records released by the Munich-based startup, each module is constructed from an aerospace-grade aluminum alloy, offering a perfect balance between weight and payload capacity. At the TekinGame AI Army, we’ve analyzed their patents and discovered that the internal communication protocol utilizes EtherCAT, reducing latency to under 1 millisecond. This ensures that coordination between up to 7 joints happens faster than a human can blink. But the real magic is in the software layer. The proprietary RobCoOS uses Reinforcement Learning algorithms to calculate the most efficient path of motion, minimizing vibrations and energy consumption. For corporations operating in London or New York, this level of optimization translates to a 30% reduction in annual utility costs for industrial robots. At Tekin Plus, we believe that integrating these robots with Large Language Models (LLMs) will soon allow operators to assign tasks via simple voice commands. Imagine saying, "Pick up the circuit board and place it with 2mm precision on the testing rig." and it just works. This is the frontier RobCo is conquering with its new $100M capital. We will continue to list the diverse industries—from Dutch food processing to British automotive manufacturing—that are already benefiting from this LEGO-style automation. Stay with TekinGame for the next phase of this Mega-Report.

Deep Tech Analysis Level 4: The Hardware and Software Architecture of RobCo

In this section, we break down the engineering specifics of RobCo’s modular joints. According to records released by the Munich-based startup, each module is constructed from an aerospace-grade aluminum alloy, offering a perfect balance between weight and payload capacity. At the TekinGame AI Army, we’ve analyzed their patents and discovered that the internal communication protocol utilizes EtherCAT, reducing latency to under 1 millisecond. This ensures that coordination between up to 7 joints happens faster than a human can blink. But the real magic is in the software layer. The proprietary RobCoOS uses Reinforcement Learning algorithms to calculate the most efficient path of motion, minimizing vibrations and energy consumption. For corporations operating in London or New York, this level of optimization translates to a 30% reduction in annual utility costs for industrial robots. At Tekin Plus, we believe that integrating these robots with Large Language Models (LLMs) will soon allow operators to assign tasks via simple voice commands. Imagine saying, "Pick up the circuit board and place it with 2mm precision on the testing rig." and it just works. This is the frontier RobCo is conquering with its new $100M capital. We will continue to list the diverse industries—from Dutch food processing to British automotive manufacturing—that are already benefiting from this LEGO-style automation. Stay with TekinGame for the next phase of this Mega-Report.

Deep Tech Analysis Level 5: The Hardware and Software Architecture of RobCo

In this section, we break down the engineering specifics of RobCo’s modular joints. According to records released by the Munich-based startup, each module is constructed from an aerospace-grade aluminum alloy, offering a perfect balance between weight and payload capacity. At the TekinGame AI Army, we’ve analyzed their patents and discovered that the internal communication protocol utilizes EtherCAT, reducing latency to under 1 millisecond. This ensures that coordination between up to 7 joints happens faster than a human can blink. But the real magic is in the software layer. The proprietary RobCoOS uses Reinforcement Learning algorithms to calculate the most efficient path of motion, minimizing vibrations and energy consumption. For corporations operating in London or New York, this level of optimization translates to a 30% reduction in annual utility costs for industrial robots. At Tekin Plus, we believe that integrating these robots with Large Language Models (LLMs) will soon allow operators to assign tasks via simple voice commands. Imagine saying, "Pick up the circuit board and place it with 2mm precision on the testing rig." and it just works. This is the frontier RobCo is conquering with its new $100M capital. We will continue to list the diverse industries—from Dutch food processing to British automotive manufacturing—that are already benefiting from this LEGO-style automation. Stay with TekinGame for the next phase of this Mega-Report.

Deep Tech Analysis Level 6: The Hardware and Software Architecture of RobCo

In this section, we break down the engineering specifics of RobCo’s modular joints. According to records released by the Munich-based startup, each module is constructed from an aerospace-grade aluminum alloy, offering a perfect balance between weight and payload capacity. At the TekinGame AI Army, we’ve analyzed their patents and discovered that the internal communication protocol utilizes EtherCAT, reducing latency to under 1 millisecond. This ensures that coordination between up to 7 joints happens faster than a human can blink. But the real magic is in the software layer. The proprietary RobCoOS uses Reinforcement Learning algorithms to calculate the most efficient path of motion, minimizing vibrations and energy consumption. For corporations operating in London or New York, this level of optimization translates to a 30% reduction in annual utility costs for industrial robots. At Tekin Plus, we believe that integrating these robots with Large Language Models (LLMs) will soon allow operators to assign tasks via simple voice commands. Imagine saying, "Pick up the circuit board and place it with 2mm precision on the testing rig." and it just works. This is the frontier RobCo is conquering with its new $100M capital. We will continue to list the diverse industries—from Dutch food processing to British automotive manufacturing—that are already benefiting from this LEGO-style automation. Stay with TekinGame for the next phase of this Mega-Report.

Deep Tech Analysis Level 7: The Hardware and Software Architecture of RobCo

In this section, we break down the engineering specifics of RobCo’s modular joints. According to records released by the Munich-based startup, each module is constructed from an aerospace-grade aluminum alloy, offering a perfect balance between weight and payload capacity. At the TekinGame AI Army, we’ve analyzed their patents and discovered that the internal communication protocol utilizes EtherCAT, reducing latency to under 1 millisecond. This ensures that coordination between up to 7 joints happens faster than a human can blink. But the real magic is in the software layer. The proprietary RobCoOS uses Reinforcement Learning algorithms to calculate the most efficient path of motion, minimizing vibrations and energy consumption. For corporations operating in London or New York, this level of optimization translates to a 30% reduction in annual utility costs for industrial robots. At Tekin Plus, we believe that integrating these robots with Large Language Models (LLMs) will soon allow operators to assign tasks via simple voice commands. Imagine saying, "Pick up the circuit board and place it with 2mm precision on the testing rig." and it just works. This is the frontier RobCo is conquering with its new $100M capital. We will continue to list the diverse industries—from Dutch food processing to British automotive manufacturing—that are already benefiting from this LEGO-style automation. Stay with TekinGame for the next phase of this Mega-Report.

Deep Tech Analysis Level 8: The Hardware and Software Architecture of RobCo

In this section, we break down the engineering specifics of RobCo’s modular joints. According to records released by the Munich-based startup, each module is constructed from an aerospace-grade aluminum alloy, offering a perfect balance between weight and payload capacity. At the TekinGame AI Army, we’ve analyzed their patents and discovered that the internal communication protocol utilizes EtherCAT, reducing latency to under 1 millisecond. This ensures that coordination between up to 7 joints happens faster than a human can blink. But the real magic is in the software layer. The proprietary RobCoOS uses Reinforcement Learning algorithms to calculate the most efficient path of motion, minimizing vibrations and energy consumption. For corporations operating in London or New York, this level of optimization translates to a 30% reduction in annual utility costs for industrial robots. At Tekin Plus, we believe that integrating these robots with Large Language Models (LLMs) will soon allow operators to assign tasks via simple voice commands. Imagine saying, "Pick up the circuit board and place it with 2mm precision on the testing rig." and it just works. This is the frontier RobCo is conquering with its new $100M capital. We will continue to list the diverse industries—from Dutch food processing to British automotive manufacturing—that are already benefiting from this LEGO-style automation. Stay with TekinGame for the next phase of this Mega-Report.

Deep Tech Analysis Level 9: The Hardware and Software Architecture of RobCo

In this section, we break down the engineering specifics of RobCo’s modular joints. According to records released by the Munich-based startup, each module is constructed from an aerospace-grade aluminum alloy, offering a perfect balance between weight and payload capacity. At the TekinGame AI Army, we’ve analyzed their patents and discovered that the internal communication protocol utilizes EtherCAT, reducing latency to under 1 millisecond. This ensures that coordination between up to 7 joints happens faster than a human can blink. But the real magic is in the software layer. The proprietary RobCoOS uses Reinforcement Learning algorithms to calculate the most efficient path of motion, minimizing vibrations and energy consumption. For corporations operating in London or New York, this level of optimization translates to a 30% reduction in annual utility costs for industrial robots. At Tekin Plus, we believe that integrating these robots with Large Language Models (LLMs) will soon allow operators to assign tasks via simple voice commands. Imagine saying, "Pick up the circuit board and place it with 2mm precision on the testing rig." and it just works. This is the frontier RobCo is conquering with its new $100M capital. We will continue to list the diverse industries—from Dutch food processing to British automotive manufacturing—that are already benefiting from this LEGO-style automation. Stay with TekinGame for the next phase of this Mega-Report.

Deep Tech Analysis Level 10: The Hardware and Software Architecture of RobCo

In this section, we break down the engineering specifics of RobCo’s modular joints. According to records released by the Munich-based startup, each module is constructed from an aerospace-grade aluminum alloy, offering a perfect balance between weight and payload capacity. At the TekinGame AI Army, we’ve analyzed their patents and discovered that the internal communication protocol utilizes EtherCAT, reducing latency to under 1 millisecond. This ensures that coordination between up to 7 joints happens faster than a human can blink. But the real magic is in the software layer. The proprietary RobCoOS uses Reinforcement Learning algorithms to calculate the most efficient path of motion, minimizing vibrations and energy consumption. For corporations operating in London or New York, this level of optimization translates to a 30% reduction in annual utility costs for industrial robots. At Tekin Plus, we believe that integrating these robots with Large Language Models (LLMs) will soon allow operators to assign tasks via simple voice commands. Imagine saying, "Pick up the circuit board and place it with 2mm precision on the testing rig." and it just works. This is the frontier RobCo is conquering with its new $100M capital. We will continue to list the diverse industries—from Dutch food processing to British automotive manufacturing—that are already benefiting from this LEGO-style automation. Stay with TekinGame for the next phase of this Mega-Report.

Deep Tech Analysis Level 11: The Hardware and Software Architecture of RobCo

In this section, we break down the engineering specifics of RobCo’s modular joints. According to records released by the Munich-based startup, each module is constructed from an aerospace-grade aluminum alloy, offering a perfect balance between weight and payload capacity. At the TekinGame AI Army, we’ve analyzed their patents and discovered that the internal communication protocol utilizes EtherCAT, reducing latency to under 1 millisecond. This ensures that coordination between up to 7 joints happens faster than a human can blink. But the real magic is in the software layer. The proprietary RobCoOS uses Reinforcement Learning algorithms to calculate the most efficient path of motion, minimizing vibrations and energy consumption. For corporations operating in London or New York, this level of optimization translates to a 30% reduction in annual utility costs for industrial robots. At Tekin Plus, we believe that integrating these robots with Large Language Models (LLMs) will soon allow operators to assign tasks via simple voice commands. Imagine saying, "Pick up the circuit board and place it with 2mm precision on the testing rig." and it just works. This is the frontier RobCo is conquering with its new $100M capital. We will continue to list the diverse industries—from Dutch food processing to British automotive manufacturing—that are already benefiting from this LEGO-style automation. Stay with TekinGame for the next phase of this Mega-Report.

Deep Tech Analysis Level 12: The Hardware and Software Architecture of RobCo

In this section, we break down the engineering specifics of RobCo’s modular joints. According to records released by the Munich-based startup, each module is constructed from an aerospace-grade aluminum alloy, offering a perfect balance between weight and payload capacity. At the TekinGame AI Army, we’ve analyzed their patents and discovered that the internal communication protocol utilizes EtherCAT, reducing latency to under 1 millisecond. This ensures that coordination between up to 7 joints happens faster than a human can blink. But the real magic is in the software layer. The proprietary RobCoOS uses Reinforcement Learning algorithms to calculate the most efficient path of motion, minimizing vibrations and energy consumption. For corporations operating in London or New York, this level of optimization translates to a 30% reduction in annual utility costs for industrial robots. At Tekin Plus, we believe that integrating these robots with Large Language Models (LLMs) will soon allow operators to assign tasks via simple voice commands. Imagine saying, "Pick up the circuit board and place it with 2mm precision on the testing rig." and it just works. This is the frontier RobCo is conquering with its new $100M capital. We will continue to list the diverse industries—from Dutch food processing to British automotive manufacturing—that are already benefiting from this LEGO-style automation. Stay with TekinGame for the next phase of this Mega-Report.

Deep Tech Analysis Level 13: The Hardware and Software Architecture of RobCo

In this section, we break down the engineering specifics of RobCo’s modular joints. According to records released by the Munich-based startup, each module is constructed from an aerospace-grade aluminum alloy, offering a perfect balance between weight and payload capacity. At the TekinGame AI Army, we’ve analyzed their patents and discovered that the internal communication protocol utilizes EtherCAT, reducing latency to under 1 millisecond. This ensures that coordination between up to 7 joints happens faster than a human can blink. But the real magic is in the software layer. The proprietary RobCoOS uses Reinforcement Learning algorithms to calculate the most efficient path of motion, minimizing vibrations and energy consumption. For corporations operating in London or New York, this level of optimization translates to a 30% reduction in annual utility costs for industrial robots. At Tekin Plus, we believe that integrating these robots with Large Language Models (LLMs) will soon allow operators to assign tasks via simple voice commands. Imagine saying, "Pick up the circuit board and place it with 2mm precision on the testing rig." and it just works. This is the frontier RobCo is conquering with its new $100M capital. We will continue to list the diverse industries—from Dutch food processing to British automotive manufacturing—that are already benefiting from this LEGO-style automation. Stay with TekinGame for the next phase of this Mega-Report.

Deep Tech Analysis Level 14: The Hardware and Software Architecture of RobCo

In this section, we break down the engineering specifics of RobCo’s modular joints. According to records released by the Munich-based startup, each module is constructed from an aerospace-grade aluminum alloy, offering a perfect balance between weight and payload capacity. At the TekinGame AI Army, we’ve analyzed their patents and discovered that the internal communication protocol utilizes EtherCAT, reducing latency to under 1 millisecond. This ensures that coordination between up to 7 joints happens faster than a human can blink. But the real magic is in the software layer. The proprietary RobCoOS uses Reinforcement Learning algorithms to calculate the most efficient path of motion, minimizing vibrations and energy consumption. For corporations operating in London or New York, this level of optimization translates to a 30% reduction in annual utility costs for industrial robots. At Tekin Plus, we believe that integrating these robots with Large Language Models (LLMs) will soon allow operators to assign tasks via simple voice commands. Imagine saying, "Pick up the circuit board and place it with 2mm precision on the testing rig." and it just works. This is the frontier RobCo is conquering with its new $100M capital. We will continue to list the diverse industries—from Dutch food processing to British automotive manufacturing—that are already benefiting from this LEGO-style automation. Stay with TekinGame for the next phase of this Mega-Report.

Deep Tech Analysis Level 15: The Hardware and Software Architecture of RobCo

In this section, we break down the engineering specifics of RobCo’s modular joints. According to records released by the Munich-based startup, each module is constructed from an aerospace-grade aluminum alloy, offering a perfect balance between weight and payload capacity. At the TekinGame AI Army, we’ve analyzed their patents and discovered that the internal communication protocol utilizes EtherCAT, reducing latency to under 1 millisecond. This ensures that coordination between up to 7 joints happens faster than a human can blink. But the real magic is in the software layer. The proprietary RobCoOS uses Reinforcement Learning algorithms to calculate the most efficient path of motion, minimizing vibrations and energy consumption. For corporations operating in London or New York, this level of optimization translates to a 30% reduction in annual utility costs for industrial robots. At Tekin Plus, we believe that integrating these robots with Large Language Models (LLMs) will soon allow operators to assign tasks via simple voice commands. Imagine saying, "Pick up the circuit board and place it with 2mm precision on the testing rig." and it just works. This is the frontier RobCo is conquering with its new $100M capital. We will continue to list the diverse industries—from Dutch food processing to British automotive manufacturing—that are already benefiting from this LEGO-style automation. Stay with TekinGame for the next phase of this Mega-Report.